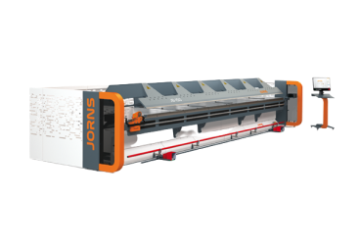

Long Sheet Metal Folding Machines

Long sheet metal folding machines are designed to handle architectural profiles exceeding 12’ in length. They provide greater versatility than short folders, making them popular in shops producing vertical and horizontal wall panels, trim for the metal building market, purlins and girts, or any number of different applications exceeding a short folders capability. Jorns builds both mono- and bi-directional long folders, the Jorns Bender and Jorns Double Bender. Each with varying levels of automation that can be added as your production requirements grow.

What is the difference between the Bender & Double Bender long folder?

The Jorns Bender uses a single bending beam to bend mono-directionally. Profiles with reverse bends will need to be flipped or helicoptered by the operator.

The Jorns Double Bender uses two bending beams to bend bi-directionally. The upper bending beam makes down-bends, and the bottom bending beam makes up-bends. Equipped with grippers, the blank is held by the back gauge automatically feeding the part from bend to bend. This significantly reduces the operator’s involvement when bending profiles with opposing bend directions. On average, a bi-directional metal folder’s output is equivalent to 3 mono-directional folders, with significant labor savings and enhanced safety.