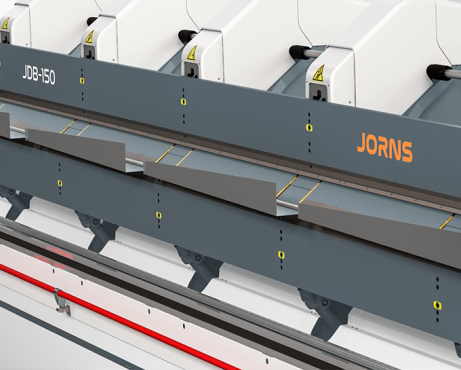

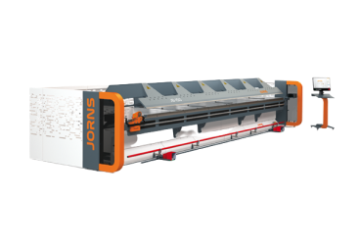

Jorns Double Bender (JDB)

Jorns JDB Double Bending machine is offered in lengths of 13, 21, 26, 32, and 40 feet as a standard (other lengs available) and can work with material up to 11g mild steel capacity.

Automation today is a critical part of manufacturing. Jorns has been providing automated solutions since the 1980’s. These years of experience has led to advances in developing automated handling systems, side loading flat sheets, integrated robotic solutions. All of this is capable of being driven through Industry 4.0 standards such as Bendex software.

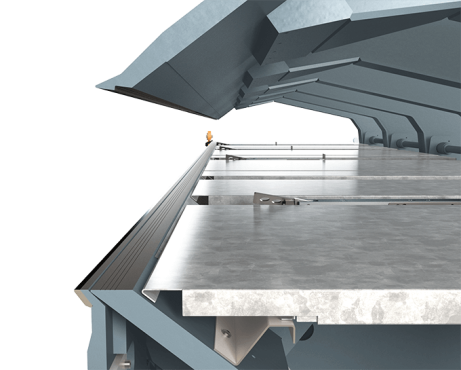

Capabilities of the Jorns JDB bending machine allow for one complete solution no matter your industry served or future needs. One bending solution provides you the ability to create profiles for the metal roofing and metal building industry.

Examples of possible profiles are corrugated roofing panels, corrugated wall panels, architect designed wall panels, tapered panels, tapered profiles for nesting solutions, as well as your needed C’s and Z’s.

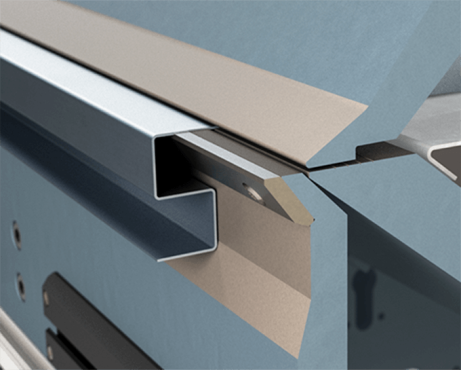

Photo: Configuration examples from the Jorns Double Bender for all aspects of architectural bending.

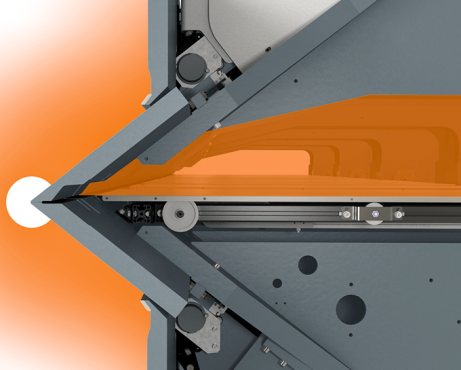

Curved Lower Beam

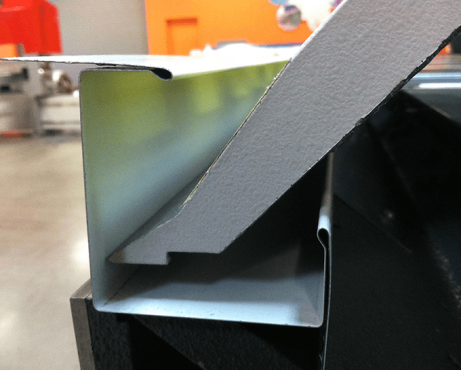

The JDB's curved lower beam makes it easy to bend and build virtually anything you need for your building. Complex geometries become easy and efficient, allowing you and your team to meet your customers' high expectations, and deliver on time and within budget.

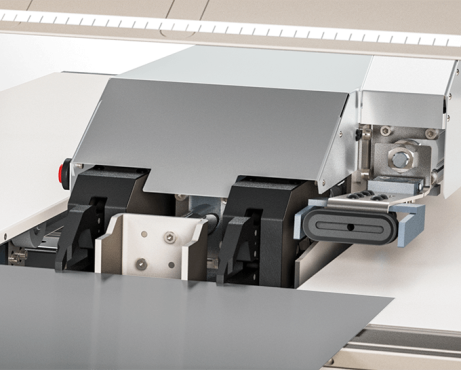

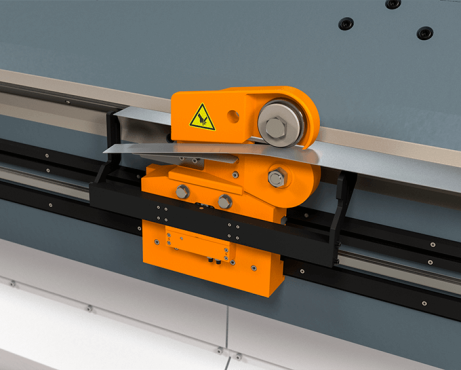

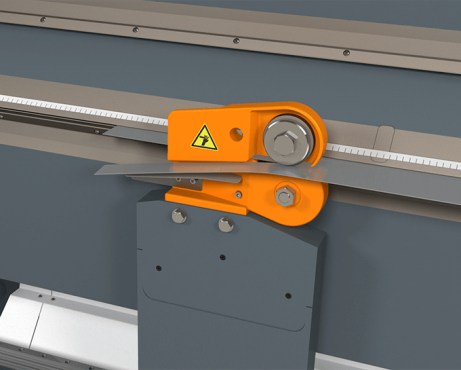

The JDB flexibility provides more possible profiles with varying dimensions possible due to the 269° front free bending space and the largest rear free space under the upper jaw.

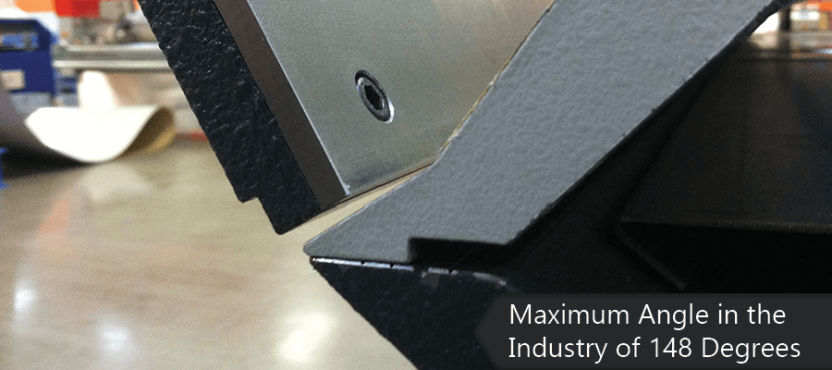

- Maximum bending angle makes all the difference

- You decide the gripper arm placement to meet your needs

- Dynamic positioning for more accuracy

- Open space inside of the tooling

- Amazing clamping pressure for more accuracy

- Bendex inside!

- Jorns conveying solutions to meet each customer's needs

- And best of all...you can automate in phases as you grow. Prep for side infeed, add JPM when you are ready

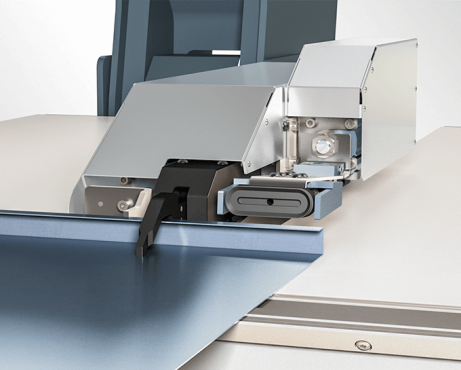

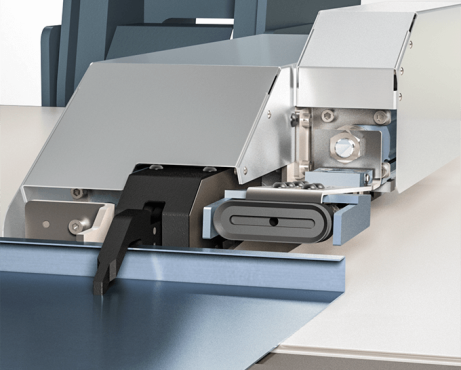

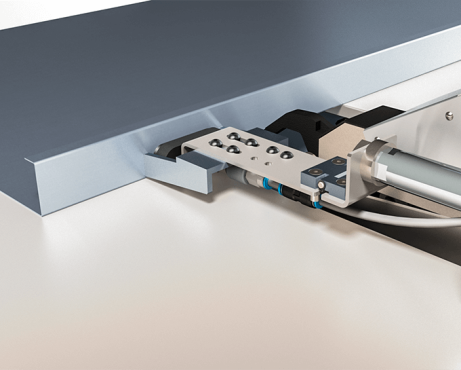

The ability to retreat the bending beam of more than 11 inches creates huge free space. Multiple gripping solutions such as, gripping positions of the material, vacuum grippers, short part clamps allow the machine to run your profiles automatically without any custom add on.

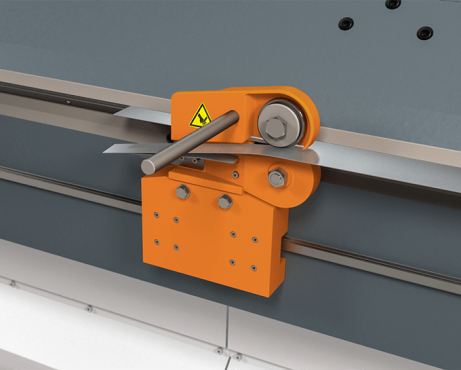

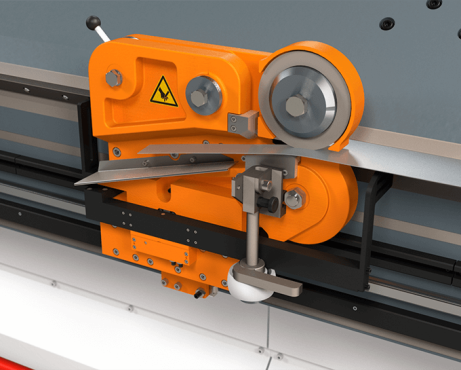

The optional high-speed slitter covering 10ft/sec, essential for tapered profiles and the exchangeable slitter head with rollform tooling adds even more flexibility in one complete system.

Modern Technology for todays challenges

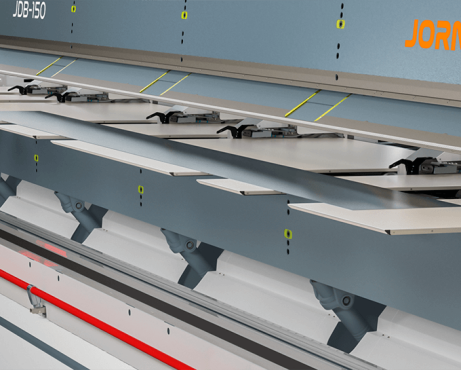

Todays technology is evident in the Jorns JDB when looking for a solution. Whether it be using the powerful graphic control with auto sequencing, zoned gripping solutions in conjunction with the automated infeed tables to allow a single operator to produce multiple parts at the same time, dynamic positioning to the optional laser hardened tooling, networkable machine tool, remote diagnostics with TeamViewer and the powerful B&R Automation Suite for servicing, Jorns is prepared for today’s needs.

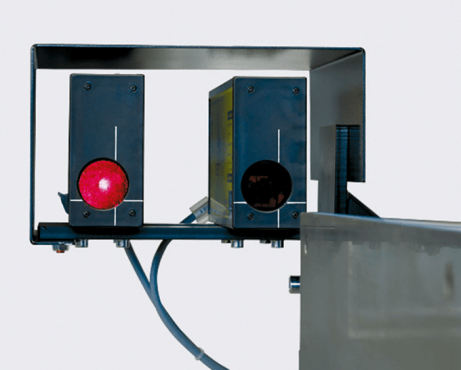

Several safety features are a standard of the Jorns JDB bending system.

Light curtain for protection during automatic machine operation, laser monitoring of the beams when needed to work inside the protected light curtain area and modern safety fencing are standard safety features. Other inherent features such as the auto infeed tables provide a safer and easier loading of flat sheet to the machine for production. The ability of the back gauge to operate at close to the bending moment in fully automatic mode provide the operator with no need for material handling until the profile is finished.

When considering all the FACTS, you will find Jorns provides you with a high performing, accurate, reliable, technically advanced, safe, automated bending machine, to enable you to be in the best position for today and tomorrow’s business.