Precision Sheet Metal Forming Solutions

Contact Us TodayProducing high-quality metal parts is no easy task, especially when working with large or heavy profiles.

Traditional bending methods often fall short of efficiently delivering accurate profiles, and today’s labor shortages only add to the cost and complexity.

MetalForming LLC delivers folding machinery designed for precision metal forming, serving manufacturers and fabricators who demand exacting tolerances and consistent results.

Our solutions strengthen critical operations from the bending department, throughout the rest of the production process.

Folding machines eliminate handling issues, and control over 90% of the bending process, enabling a single operator to safely and efficiently bend large or complex parts with exceptional accuracy. This results in greatly reduced operator fatigue and part variability, keeping production steady from start to finish.

With our full range of advanced precision metal folding equipment and deep in-house expertise, we help companies lean our their fabrication process, from start to finish.

What Is Precision Sheet Metal Forming?

Precision Sheet Metal Forming is the disciplined process of bending metal into exact specifications with repeatable, predictable results. It’s more than just bending, it’s the integration of high-impact technologies to achieve consistent, tight-tolerance parts, regardless of part size or complexity.

In modern fabricating, folding technology stands out as the most effective path to precision. By automating over 90% of the handling and control, folding systems minimize operator influence, reduce physical strain, and ensure uniform results from the first part to the last. This directly supports the Factors 4 Folding:

-

Reduced Labor – One operator can manage large, complex parts without the need for multiple hands or specialized teams.

-

Reduced Handling – The machine holds, positions, and supports the workpiece, minimizing material movement and the risk of damage.

-

Improved Accuracy – Automated gauging and controlled motion deliver consistent precision, eliminating guesswork.

-

Better Downstream Operations (DSOs) Performance – Faster throughput, fewer reworks, and consistent quality shorten lead times and improve cash flow.

Precision Sheet Metal Forming isn’t just about making parts, it’s about creating a controlled, repeatable process that delivers quality, efficiency, and profitability in every run. With the right equipment, manufacturers can meet the demands of today’s market while building a competitive advantage for tomorrows needs.

Comprehensive Precision Metal Forming Equipment and Machinery

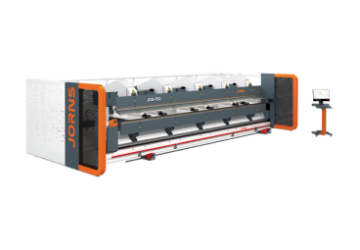

Precision metal forming requires purpose-built machinery that delivers reliable results in even the most complex manufacturing environments. That’s why MetalForming offers a full range of folders and coil processors to enable fabricators to remain competitive in a labor-constrained, high-mix manufacturing environment including:

- Long sheet metal folding machines to achieve consistent angle formation

- Short sheet metal folding machines to reliably fold sheet metal using a 10 or 13 foot bending length

- Coil processors to accurately decoil, slit or wind your metal materials

Each machine drives quality, productivity, and repeatable performance on every production floor.

Shop Equipment Ready to Meet Your Needs

Why Choose MetalForming’s Precision Folding Technology?

Factors 4 Folding

1. Reduce Labor

One Operator: Folding eliminates flipping, supporting, and excessive handling, so one operator can safely manage parts with ease.

Reduced Costs: Simpler process minimize operator requirements and skill demands, resulting in measurable cost savings.

Higher Productivity: When labor is limited, efficiency matters. A streamlined bending process keeps output high, even with fewer hands.

2. Eliminate Handling Challenges

Improved Control: Over 90% of the part is in the hands of a press brake operator, folders take charge of the handling so the operator doesn’t need to.

Consistency: The folder controls over 90% of the process, eliminating size related issues while maintaining consistent production time.

Minimal Strain: With automated gauging and part support, even large, heavy parts are easily managed by a single operator.

3. Unmatched Accuracy

Ignore Material Variations: A folder bends in a way that minimizes the effects of thickness and tensile variations, maintaining part accuracy without operator intervention.

Fewer Errors: Referencing flange lengths from a single datum point eliminates cumulative errors that compromise part fitment.

Higher Productivity: Better precision means smoother welding, faster assembly, fewer errors, and higher efficiency.

4. Streamline Downstream Operations (DSOs)

Seamless Fit: Consistent bends mean parts fit together easily, cutting down on rework, adjustments, and assembly time.

Precision-Formed Parts: Eliminate misalignment to boost welding speed, cut fixture costs, and improve robotic performance.

Fewer Bottlenecks: Consistent speeds and tight tolerances reduce bottlenecks and keep production moving.

Best-in-Class Support for Precision Manufacturing

Purchasing new precision metal forming equipment marks the start of your improved workflow. However, without the right services and support, your machine can become less productive over time.

That’s why MetalForming is dedicated to being your one partner in the precision industry. Technicians are trained in the factory where your machine was built so you can be assured you are in the most capable hands. Our talented services team provides comprehensive support tailored to meet the evolving needs of your business. Focus on what you do best while your metal forming needs are met by a support team with a myriad of capabilities and experience.

MetalForming creates a comprehensive approach in order to meet your precision folding needs by integrating software and equipment to optimize efficiency. Look no further for a trusted and reliable partner with service capabilities including:

- Application Support

- Field Support

- Remote Support

- Replacement Parts

- Service Level Agreements

- Training

Discover the MetalForming Advantage and Request a Quote Today

MetalForming partners with premium vendors to deliver the most advanced precision sheet metal formers on the market. We provide equipment, software, training, and consulting services that enable our customers to make their mark and build their brands.

From trusted services to industry-recognized certifications, MetalForming LLC is North America’s leading name in precision sheet metal forming.

Contact us to request a demo, review equipment specs, or get a quote tailored to your fabrication goals.

![precision-metal-folding-technology-enables-kit-manufacturing-1693400548-min[1].jpg](/assets/components/phpthumbof/cache/precision_metal_folding_technology_enables_kit_manufacturing_1693400548_min_1.45873a49550da719ede5706b1ac1e115.jpg)

![precision-metal-folding-technology-enables-kit-manufacturing-1693400562-min[1].jpg](/assets/components/phpthumbof/cache/precision_metal_folding_technology_enables_kit_manufacturing_1693400562_min_1.45873a49550da719ede5706b1ac1e115.jpg)

![precision-metal-folding-technology-enables-kit-manufacturing-1693400566-min[1].jpg](/assets/components/phpthumbof/cache/precision_metal_folding_technology_enables_kit_manufacturing_1693400566_min_1.45873a49550da719ede5706b1ac1e115.jpg)

![precision-metal-folding-technology-enables-kit-manufacturing-1693400571-min[1].jpg](/assets/components/phpthumbof/cache/precision_metal_folding_technology_enables_kit_manufacturing_1693400571_min_1.45873a49550da719ede5706b1ac1e115.jpg)

![precision-metal-folding-technology-enables-kit-manufacturing-1693400577-min[1].jpg](/assets/components/phpthumbof/cache/precision_metal_folding_technology_enables_kit_manufacturing_1693400577_min_1.45873a49550da719ede5706b1ac1e115.jpg)

![precision-metal-folding-technology-enables-kit-manufacturing-1693400543-min[1].jpg](/assets/components/phpthumbof/cache/precision_metal_folding_technology_enables_kit_manufacturing_1693400543_min_1.45873a49550da719ede5706b1ac1e115.jpg)